API Tubing Solutions with Superior Quality

Our API Tubing

Your Premier Source for Comprehensive API Tubing Solutions Across North America

As a renowned manufacturer of premium Oil Country Tubular Goods (OCTG), we specialize in providing cutting-edge tubing solutions for conventional, offshore, and unconventional oil and gas projects. Our expertise spans across the entire industry, from drilling to completion, and we are dedicated to delivering innovative solutions that address even the most complex challenges.

Impressive Tubing Manufacturing

With an impressive annual manufacturing capacity of 35 million feet, our Houston-based North American team is equipped to meet your needs, saving you time and money while eliminating unnecessary complexities both now and in the future

API Tubing Features & Benefits

- Vertically integrated manufacturing ensuring superior quality

- Extensive QA/QC exceeding the highest industry standards

- Multiple heat-treat lines to meet industries high volume

- Easy to do business with reliable service

- Proximity to most active plays – Permian Basin, Eagle Ford, Rocky Mountains, Oklahoma, and more

Tejas API Tubing Specifications

API Tubing QA

API Tubing Manufacturing & Quality Assurance

Tejas Tubular manufactures API tubing to the highest standards of precision, quality, and consistency. Each stage of our process is performed in-house, ensuring complete control over material properties, dimensional accuracy, and API compliance.

OCTG-Grade Steel

We source premium API tubing from trusted mills, ensuring that our tubing begins with the highest quality of raw steel engineered for oilfield demands.

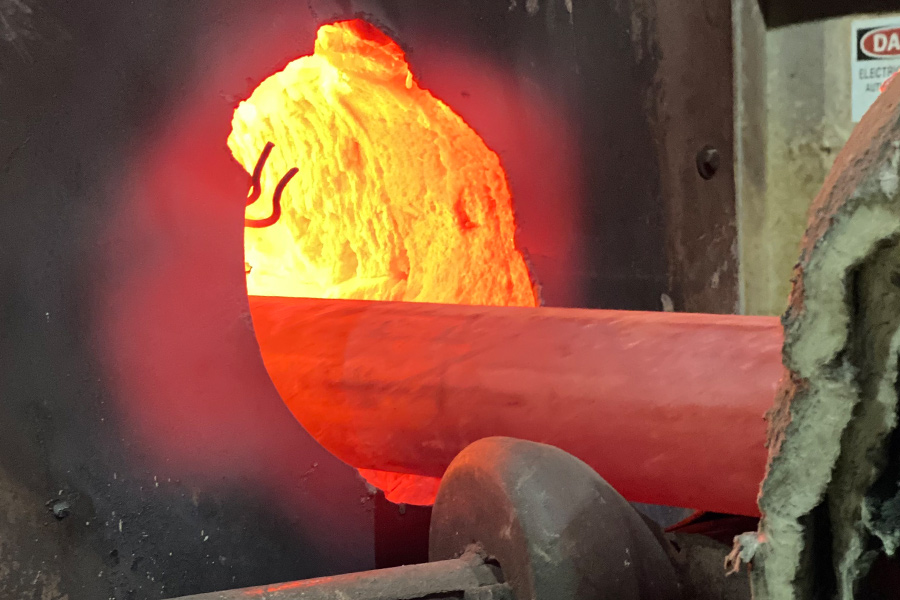

Tubing Heat Treatment

Our facility has several heat-treat lines that utilize induction, gas-fired furnaces, and two distinct heat treatment methods: quench and temper, and normalizing.

Straightening

After heat treatment, tubing passes through cross-roll straighteners to correct any minor bending and ensure true alignment for downstream operations.

Upsetting

Our in-house upsetters empower us with the expertise to skillfully hot forge tubing ends while strictly complying with API specifications. Furthermore, we provide the versatility to tailor these ends to match the unique demands of our esteemed clientele precisely.

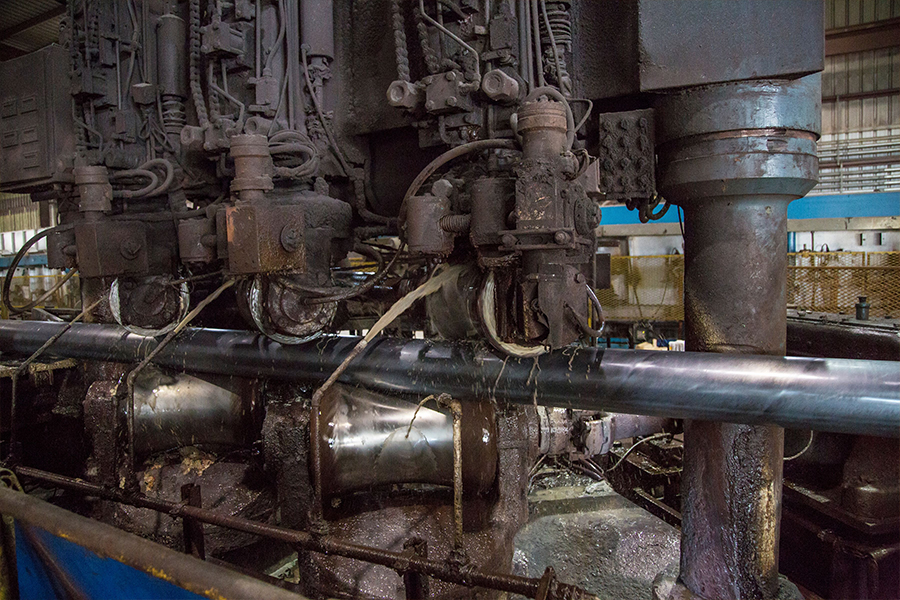

Precision Threading Exceeds Standards

We use precision CNC machines and automated systems for consistent API threading. Our tight tolerance control ensures superior fit, seal performance, and ease of make-up.

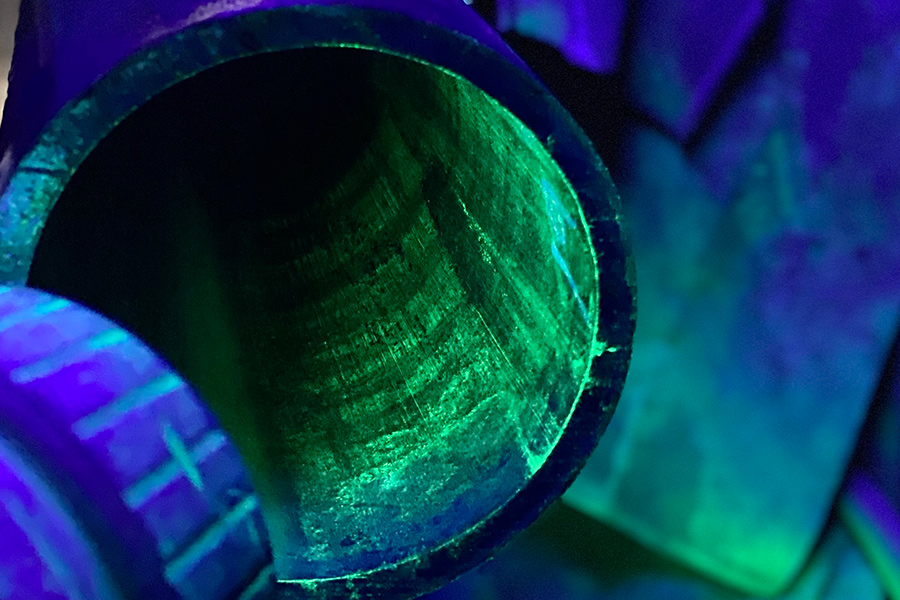

Special End Area (SEA) Inspection

Each tubing end undergoes wet magnetic particle inspection to identify surface or near-surface defects before threading.

EMI Inspection & Hydro Testing

Electromagnetic inspection units continuously check the tubing body for longitudinal and transverse flaws, wall thickness, and grade uniformity.

Plus, all tubing is hydrostatically tested to API 5CT specifications to verify pressure integrity and strength.

Coating

Our couplings proceed to our painting facility to ensure each coupling receives a unique color coating, adding a personalized touch to our quality craftsmanship.

It’s All About Connections!

Tejas Tubular is your #1 Resource for quality manufacturing,

engineering, project management and service.

PREMIUM TTWS

TTWS Connection is a threaded and coupled, high torque, six threads per inch, double start with straight-to-taper, providing deeper stabbing and faster make-ups.

PREMIUM TTS-6 Black

Our premium TTS-6 connections are designed to meet and exceed the challenges of today’s energy exploration and production needs.

PREMIUM TTS-8

Our premium TTS-8 connections are designed to exceed the challenges of today’s energy exploration and production needs.

API TUBING

Since 1990, we have proudly stood as North America’s leading and most comprehensive API tubing provider.

PUP JOINTS

Our pup joints are manufactured from the highest quality API seamless tubing and per API 5CT requirements.

COUPLINGS

Our coupling is crafted from coupling stock carefully selected from top-tier seamless mills.

PROTECTORS

Our protectors are exclusively fabricated for TT pipes, safeguarding your investment from environmental factors.

DRILL PIPE

Manufacture drill pipes that adhere to API standards as well as horizontal directional drill rods.

Crossovers

Tejas provides crossovers facilitating seamless connections between varying tube configurations and connection types.

Ready to Connnect?

If you’re ready to experience better performance, less NPT, and more efficient drilling and completions operations, Tejas Tubular is ready to start the conversation. Contact us today.