Pup Joints

Pup Joints: Quality API Pup Joints You Can Rely On

Our OCTG pup joints are engineered for high-performance oilfield applications. Manufactured in the USA, Tejas Tubular delivers precision-threaded pup joints with unmatched quality, turnaround, and customization.

Key Benefits

Why Choose Tejas Tubular Pup Joints?

High-Volume API Pup Joint Manufacturing

As North America’s largest producer of API 5CT compliant pup joints, Tejas Tubular delivers unmatched volume capacity and reliability to oilfield operations.

OCTG-Grade Seamless Tubing Inputs

We manufacture our pup joints using high-grade seamless tubing to ensure maximum strength, pressure tolerance, and oilfield durability.

Integrated Heat Treating, Threading & Testing

We control every stage in-house — from CNC threading and full-body ultrasonic inspection to heat treatment — ensuring each joint meets API 5CT specs.

Fast Turnaround, Nationwide Delivery

Located near major oil plays in Texas, Colorado, and Oklahoma, we offer rapid delivery of pup joints to reduce downtime on your rigs.

Built-to-Spec Custom Threaded Pup Joints

Get pup joints in the lengths, grades, and connections you need — including EUE, NUE, and premium threads — all machined to exact tolerance.

Certified for Critical Well Conditions

All our oilfield pup joints are API 5CT certified and undergo ultrasonic inspection to meet the highest safety and performance standards.

Pup Joint QA

API Pup Joint Manufacturing & Quality Assurance

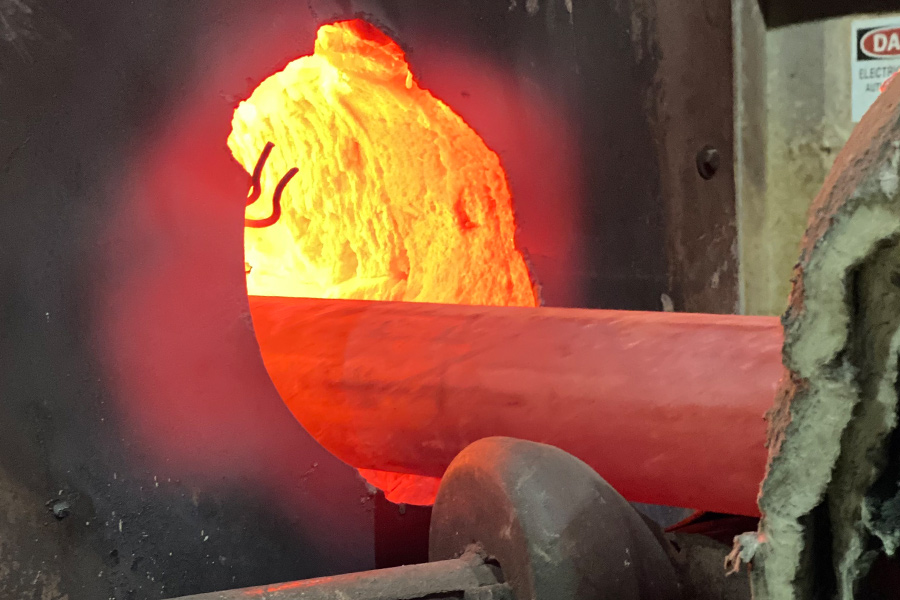

Heat Treatment

Our facilities feature induction and gas-fired furnaces capable of quench & temper (Q&T), normalize & temper (N&T), and normalizing processes. This ensures every pup joint achieves uniform hardness, strength, and toughness for long-term field reliability.

Straightening

To maintain the tight dimensional tolerances required for short-length tubulars, each pup joint undergoes a precision straightening process after tempering. This guarantees true alignment and proper thread engagement during make-up and installation.

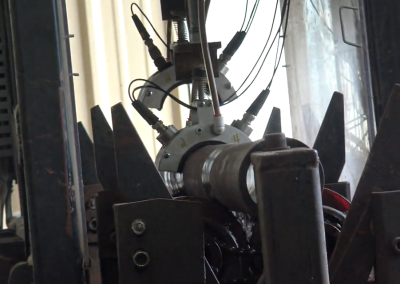

Hydro Testing

Each pup joint is hydrostatically tested in-line to confirm pressure integrity. Our custom-built plain-end hydro tester can achieve pressures up to 20,000 psi, providing assurance for both standard API and custom high-pressure applications.

OCTG-Grade Steel

We source premium seamless tubing from trusted mills, ensuring that every pup joint begins with raw material engineered for oilfield demands.

Ultrasonic Inspection

We employ full-body ultrasonic testing to detect internal flaws, cracks, and imperfections within each pup joint’s wall thickness and interior diameter. This advanced inspection ensures the highest structural integrity and product safety in the field.

Precision Threading

Our CNC machines perform precision threading that meets or exceeds API standards. Each pup joint is finished on automated production lines to guarantee consistent thread form, tight tolerances, and smooth make-up. We offer standard and premium thread types for compatibility with Tejas Tubular couplings and connections.

Tejas Pup Joint Specifications

• Premium upsets

• Perforated pup joints with our standard pattern or perforated to your specification

• J-55 full body normalized after upset upon request

• Longer length than 12' upon request

• Crossover connections

• Gas lift mandrel

Pup Joints FAQs

Frequently Asked Questions?

What are API pup joints?

API pup joints are short sections of oilfield tubing used to adjust the length of production strings. Tejas manufactures them to API 5CT specifications for reliable integration into your OCTG assemblies.

Are your pup joints API 5CT compliant?

Yes. Every pup joint is built from seamless tubing, heat treated, threaded, hydrotested, and ultrasonically inspected to meet or exceed API 5CT standards.

Do you offer custom length pup joints?

We manufacture pup joints in standard sizes from 2′ to 12′ and can accommodate custom lengths upon request. We also offer special configurations for gas lift or crossover applications.

What thread connections are available?

We offer EUE and NUE pup joints, as well as USS Buttress and premium thread connections — all machined in-house to tight tolerances.

Get API Pup Joints Built to Your Specs Today

Backed by decades of experience, Tejas delivers the quality you need — on time, every time. Contact us today to request a quote or technical data sheet.

It’s All About Connections!

Tejas Tubular is your #1 Resource for quality manufacturing,

engineering, project management and service.

PREMIUM TTWS

TTWS Connection is a threaded and coupled, high torque, six threads per inch, double start with straight-to-taper, providing deeper stabbing and faster make-ups.

PREMIUM TTS-6 Black

Our premium TTS-6 connections are designed to meet and exceed the challenges of today’s energy exploration and production needs.

PREMIUM TTS-8

Our premium TTS-8 connections are designed to exceed the challenges of today’s energy exploration and production needs.

API TUBING

Since 1990, we have proudly stood as North America’s leading and most comprehensive API tubing provider.

PUP JOINTS

Our pup joints are manufactured from the highest quality API seamless tubing and per API 5CT requirements.

COUPLINGS

Our coupling is crafted from coupling stock carefully selected from top-tier seamless mills.

PROTECTORS

Our protectors are exclusively fabricated for TT pipes, safeguarding your investment from environmental factors.

DRILL PIPE

Manufacture drill pipes that adhere to API standards as well as horizontal directional drill rods.

Crossovers

Tejas provides crossovers facilitating seamless connections between varying tube configurations and connection types.

Ready to Connnect?

If you’re ready to experience better performance, less NPT, and more efficient drilling and completions operations, Tejas Tubular is ready to start the conversation. Contact us today.