Tejas Tubular Couplings

Couplings: Innovative Coupling Solutions For Every Need

Reliable Supply, Rugged Design and Proven Performance

All our products are put through extensive non-destructive inspections to ensure the highest quality, durability, and performance. Every coupling manufactured is inspected to API requirements using wet magnetic particle inspection. This inspection detects surface and shallow subsurface defects. The couplings are inspected for longitudinal and transverse defects using this method.

Couplings KEY BENEFITS

- In-house engineering and product design team

- Extensive QA/QC

- Special couplings are available within 24 hours

- Large supply chain

- Proximity to major plays in the Permian Basin, Colorado, Oklahoma, and more

Couplings Available

Tubing Couplings

• Bevel one end or both ends

• Seal ring couplings (modified)

Casing Couplings

• SLIP x SLIP

• LTC x 8V

• Crossover couplings

• Seal ring couplings (Modified)

Flow Couplings

Blast Joints

Water Well Couplings

Couplings QA

Couplings Manufacturing & Quality Assurance

Our comprehensive family of quality couplings is engineered and manufactured from the best coupling stock, carefully sourced, and selected from seamless mills.

Coupling Stock

High-quality seamless coupling stock from picked mills.

Premium Cuts

Utilizing high-speed production band saws, our skilled team expertly cuts premium tubes to precise lengths and square dimensions, ensuring optimal fit for couplings.

Special End Area (SEA) Inspection

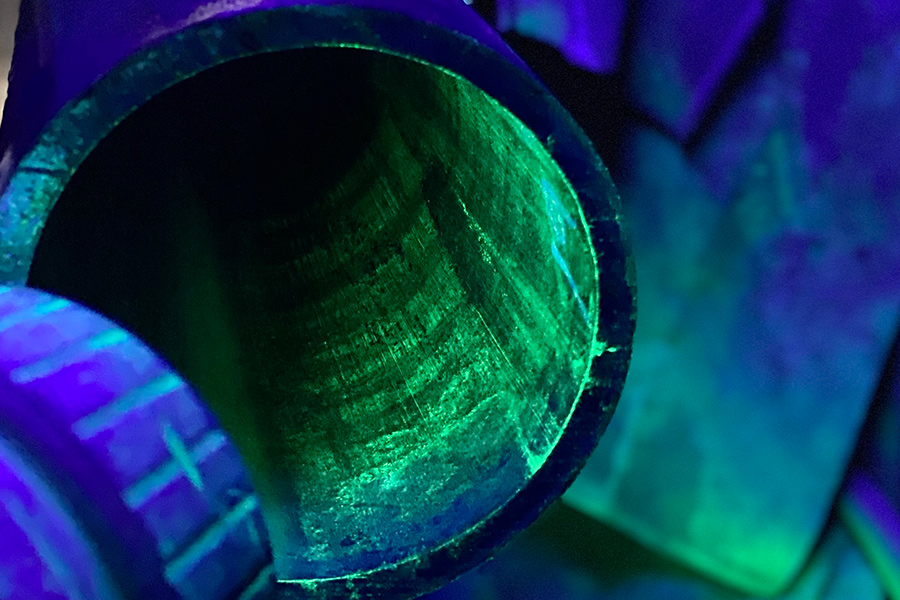

Wet magnetic particle testing detects surface and shallow subsurface defects in non-destructive testing, including longitudinal and transverse defects.

Phosphate

This procedure enhances corrosion resistance and establishes a robust bond, laying the groundwork for subsequent painting.

Precision Threading

Our commitment to precision threading is exemplified by our use of cutting-edge CNC machines and automated machining technology. These advanced tools ensure that all our couplings not only meet but exceed API standards, providing a perfect fit for your specific requirements.

Coating

Our couplings proceed to our painting facility to ensure each coupling receives a unique color coating, adding a personalized touch to our quality craftsmanship.

It’s All About Connections!

Tejas Tubular is your #1 Resource for quality manufacturing,

engineering, project management and service.

PREMIUM TTWS

TTWS Connection is a threaded and coupled, high torque, six threads per inch, double start with straight-to-taper, providing deeper stabbing and faster make-ups.

PREMIUM TTS-6 Black

Our premium TTS-6 connections are designed to meet and exceed the challenges of today’s energy exploration and production needs.

PREMIUM TTS-8

Our premium TTS-8 connections are designed to exceed the challenges of today’s energy exploration and production needs.

API TUBING

Since 1990, we have proudly stood as North America’s leading and most comprehensive API tubing provider.

PUP JOINTS

Our pup joints are manufactured from the highest quality API seamless tubing and per API 5CT requirements.

COUPLINGS

Our coupling is crafted from coupling stock carefully selected from top-tier seamless mills.

PROTECTORS

Our protectors are exclusively fabricated for TT pipes, safeguarding your investment from environmental factors.

DRILL PIPE

Manufacture drill pipes that adhere to API standards as well as horizontal directional drill rods.

Crossovers

Tejas provides crossovers facilitating seamless connections between varying tube configurations and connection types.

Ready to Connnect?

If you’re ready to experience better performance, less NPT, and more efficient drilling and completions operations, Tejas Tubular is ready to start the conversation. Contact us today.