Tejas Tubular Casing

Casing: Innovative Casing Solutions For Every Need

Efficient Casing Processing with Emphasis on Quality and Swift Turnaround

Explore Our Cutting-Edge Casing Facility in Houston, Texas, Processing Over 200,000 Tons Annually. Distinguished by our unique hot-sizing and hot-straightening capabilities, our plant stands as an industry pioneer, offering unmatched processing excellence. As a leading name in North America’s casing processing realm, we boast substantial processing capacity. Your casing products transform under the expert guidance of our seasoned professionals – the best in the field.

Adaptable to your specific requirements, our agile team ensures your needs are met. Our rigorous quality system underscores our commitment to precision, guaranteeing meticulous process control across all operations, resulting in the delivery of paramount quality products.

Casing KEY BENEFITS

- Unique heat treat setup with induction and gas-fired equipment guaranteeing tighter process control

- In-line hot sizing and straightening is our standard procedure

- Our heat treatment facility is well-suited for sour service grades and pipe requiring high collapse values

- Can heat treat up to 9 5/8″

- Can thread up to 13 3/8″

Tejas Casing Specifications

Casing QA

Casing Manufacturing & Quality Assurance

Tejas Tubular manufactures API casing using a fully integrated process that ensures strength, reliability, and dimensional accuracy. Every step—from heat treatment to hot sizing, inspection, and threading—is performed in-house under strict API 5CT and customer specifications.

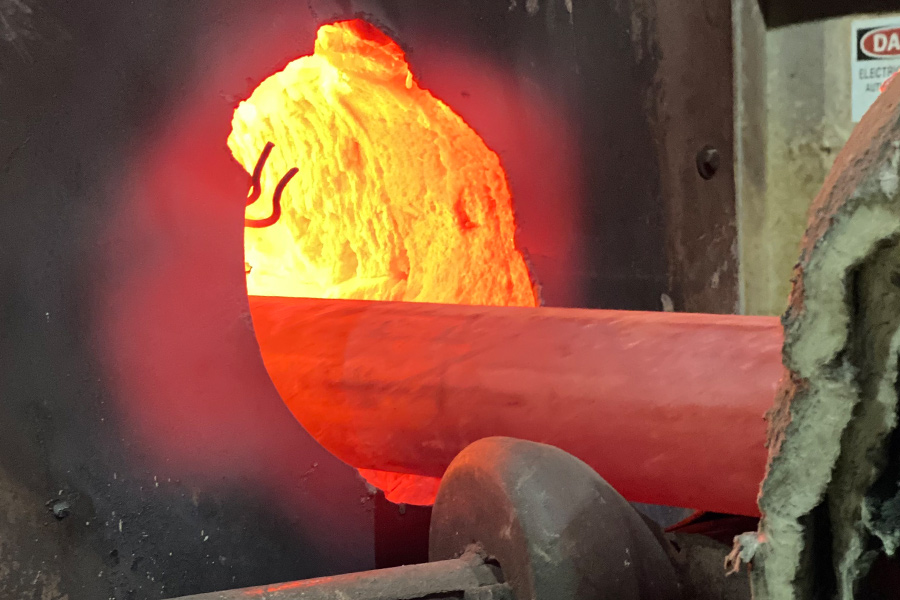

Heat Treatment

We use specialized heat-treat furnaces for consistent metallurgical properties. Our induction and gas-fired lines perform quench & temper, normalizing, and normalize & temper processes to achieve the required mechanical strength and toughness.

Ultrasonic Weld-Line Inspection (UTWL)

EMI Inspection

Our dedicated EMI units conduct continuous inspections of pipe bodies, assessing longitudinal and transverse qualities, wall thickness, and component grades. These units are equipped to handle pipe outer diameters ranging from 2 3/8″ to 9 5/8″.

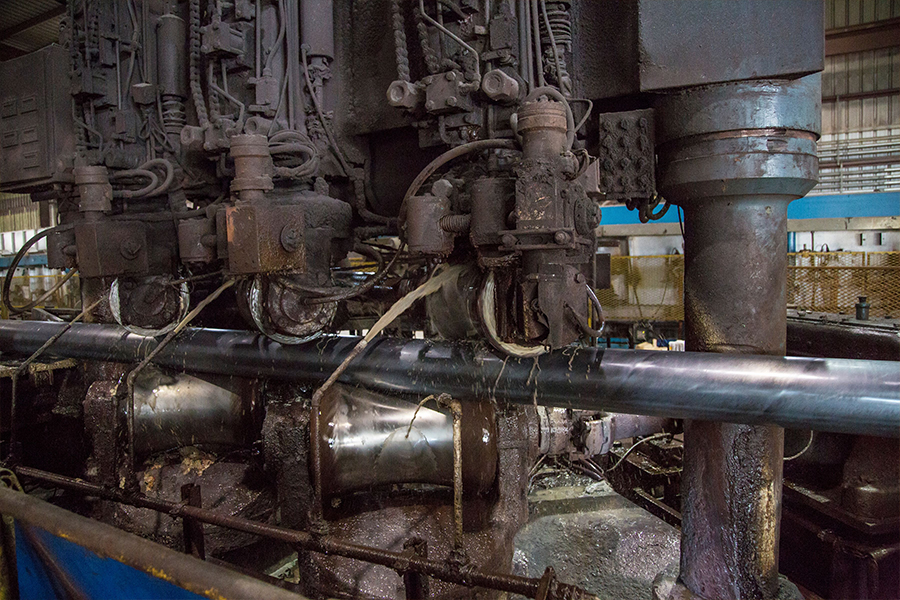

Hot Sizing & Hot Straightening

Fully Equipped Mechanical Testing Laboratory

Our casings undergo rigorous non-destructive testing to ensure high quality and reliability. You can trust that our products meet the highest standards.

Precision Threading

CNC machines and automated systems produce precise threading that meets or exceeds API and customer requirements. Each thread is checked for fit, seal integrity, and dimensional accuracy.

It’s All About Connections!

Tejas Tubular is your #1 Resource for quality manufacturing,

engineering, project management and service.

PREMIUM TTWS

TTWS Connection is a threaded and coupled, high torque, six threads per inch, double start with straight-to-taper, providing deeper stabbing and faster make-ups.

PREMIUM TTS-6 Black

Our premium TTS-6 connections are designed to meet and exceed the challenges of today’s energy exploration and production needs.

PREMIUM TTS-8

Our premium TTS-8 connections are designed to exceed the challenges of today’s energy exploration and production needs.

API TUBING

Since 1990, we have proudly stood as North America’s leading and most comprehensive API tubing provider.

PUP JOINTS

Our pup joints are manufactured from the highest quality API seamless tubing and per API 5CT requirements.

COUPLINGS

Our coupling is crafted from coupling stock carefully selected from top-tier seamless mills.

PROTECTORS

Our protectors are exclusively fabricated for TT pipes, safeguarding your investment from environmental factors.

DRILL PIPE

Manufacture drill pipes that adhere to API standards as well as horizontal directional drill rods.

Crossovers

Tejas provides crossovers facilitating seamless connections between varying tube configurations and connection types.

Ready to Connnect?

If you’re ready to experience better performance, less NPT, and more efficient drilling and completions operations, Tejas Tubular is ready to start the conversation. Contact us today.