Tejas Tubular Drill Pipe

HDD Drill Pipe Solutions From Start To Finish

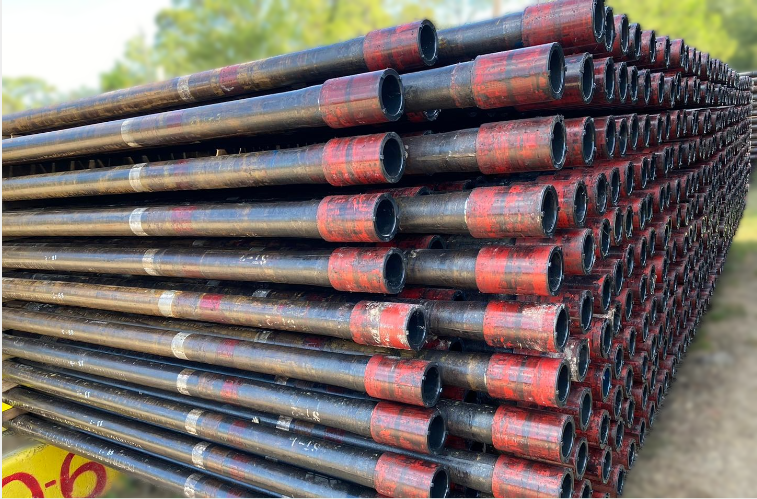

Through our partnership with Premier Drill Products, we can process all our HDD drill pipe from start to finish.

Manufacturing HDD drill pipe is serious business and our partner, Premier Drill Products, brings serious machinery, knowledge, and processes to an industry which demands a high degree of attention to detail. We require the same level of attention to detail and manufacturing quality controls as we expect for our oilfield drill pipe. Just because the pipe is smaller, does not mean the job is less important.

Manufacturing HDD drill pipe is serious business and our partner, Premier Drill Products, brings serious machinery, knowledge, and processes to an industry which demands a high degree of attention to detail. We require the same level of attention to detail and manufacturing quality controls as we expect for our oilfield drill pipe. Just because the pipe is smaller, does not mean the job is less important.

Other manufacturers depend on outside vendors to supply heat treatment. Our sister company enables us to save time and money, without sacrificing turnarounds or quality standards.

HDD Drill Pipe Specifications

American Auger , American Open Hole , Ditch Witch , DS , IF and NC connections , Vermeer

Drill Pipe Specifications

Rotary shoulder

• Hard banding

Get Drill Pipe for Your Specs Fast

Backed by decades of experience, Tejas delivers the quality you need — on time, every time. Contact us today to request a quote or technical data sheet.

Drill Pipe QA

Drill Pipe Manufacturing & Quality Assurance

Tejas Tubular manufactures API drill pipe with precision-forged upsets, controlled heat treatment, and rigorous non-destructive testing. Every step is designed to ensure durability, strength, and performance under the extreme stresses of drilling operations.

OCTG-Grade Steel

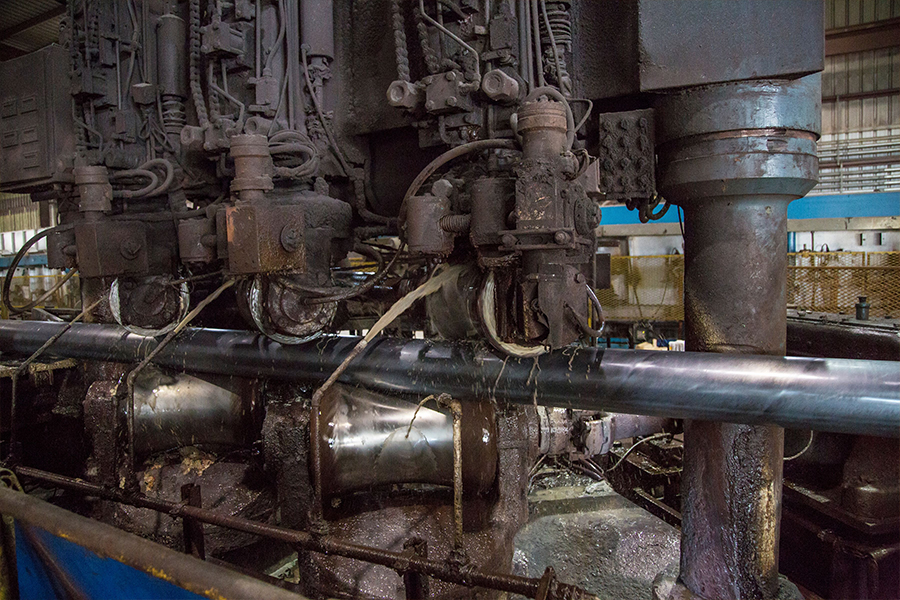

All drill pipe begins with high-grade seamless steel tubing sourced from qualified mills. Each length is inspected for dimensional accuracy and chemical composition before processing.

Upsetting

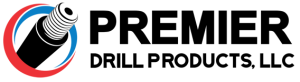

Using in-house upsetters, tubing ends are hot forged according to API specifications to achieve the proper wall thickness transition for tool joints and connections.

Heat Treatment

Our induction and gas-fired furnaces perform quench & temper and normalize & temper processes to achieve the required mechanical properties and toughness for drilling applications.

Non-Destructive Testing (UTWL & EMI)

Every pipe undergoes Ultrasonic Weld-Line (UTWL) and Electromagnetic (EMI) inspection to detect internal and surface flaws, ensuring structural integrity and API compliance.

Straightening

After heat treatment, each pipe is hot or cross-roll straightened to achieve precise straightness tolerances and uniform wall distribution.

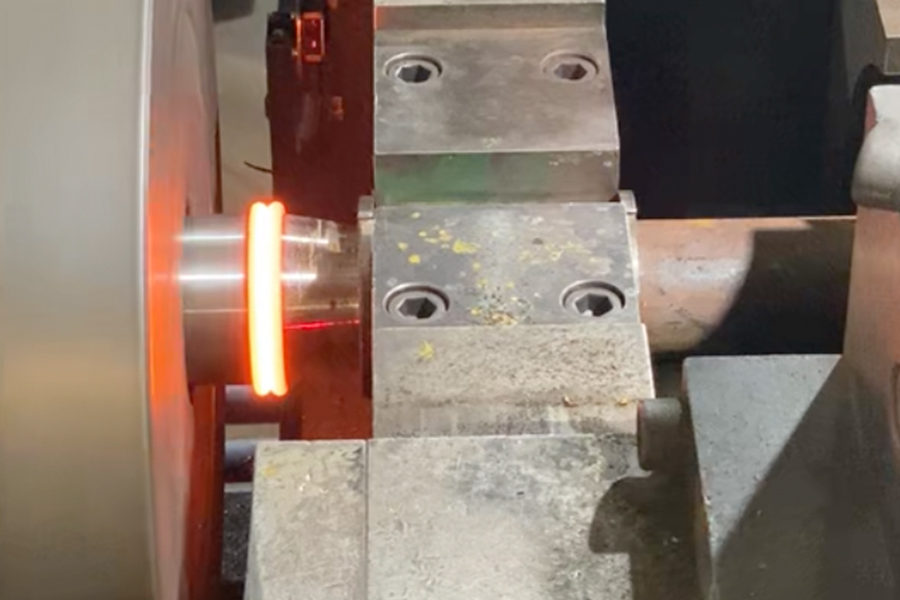

Weld Prep: “Turn & Face”

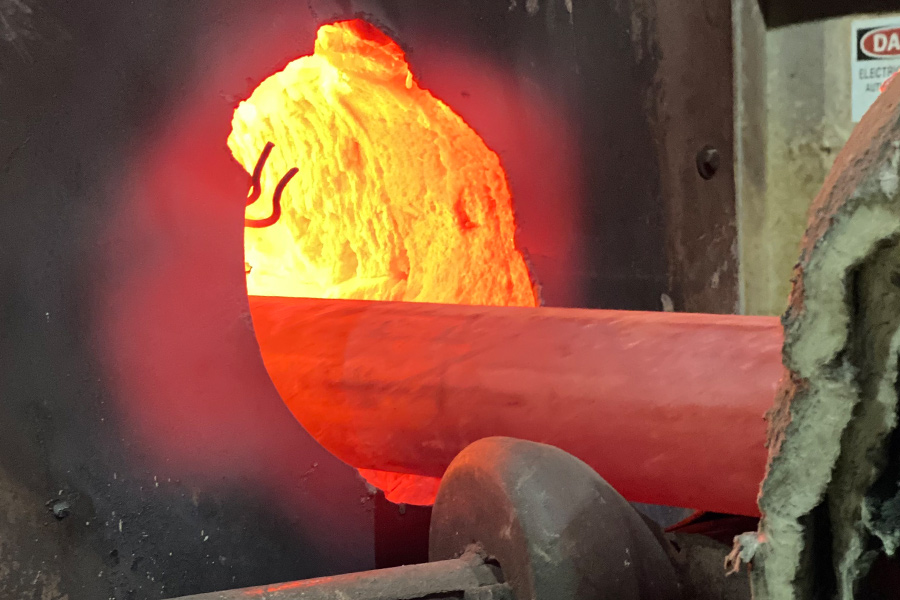

In order to get the best, and most consistent, weld on the inertia welder, the forged tubes need to have their outside diameters turned down and their weld surfaces machined (facing). This ensures that the weld area on each part being fused is equal in diameter and, that the faces are bonding uniformly during the inertia weld process.

Welding & Assembly

In partnership with Premier Drill Products, tool joints are friction welded to the pipe body under precise, controlled conditions. Each weld is inspected using ultrasonic and magnetic particle testing to ensure API 5DP compliance and consistent joint integrity.

Threading

Advanced CNC machining systems create precision API rotary shouldered connections. Thread geometry and finish are verified to ensure proper makeup torque and tight sealing.

Hardbanding

Phosphate & Coating

Threads are phosphate-treated to reduce galling during assembly, and each pipe receives a protective coating for corrosion resistance and easy identification.

To learn more about our manufacturing process, click the button below.

It’s All About Connections!

Tejas Tubular is your #1 Resource for quality manufacturing,

engineering, project management and service.

PREMIUM TTWS

TTWS Connection is a threaded and coupled, high torque, six threads per inch, double start with straight-to-taper, providing deeper stabbing and faster make-ups.

PREMIUM TTS-6 Black

Our premium TTS-6 connections are designed to meet and exceed the challenges of today’s energy exploration and production needs.

PREMIUM TTS-8

Our premium TTS-8 connections are designed to exceed the challenges of today’s energy exploration and production needs.

API TUBING

Since 1990, we have proudly stood as North America’s leading and most comprehensive API tubing provider.

PUP JOINTS

Our pup joints are manufactured from the highest quality API seamless tubing and per API 5CT requirements.

COUPLINGS

Our coupling is crafted from coupling stock carefully selected from top-tier seamless mills.

PROTECTORS

Our protectors are exclusively fabricated for TT pipes, safeguarding your investment from environmental factors.

DRILL PIPE

Manufacture drill pipes that adhere to API standards as well as horizontal directional drill rods.

Crossovers

Tejas provides crossovers facilitating seamless connections between varying tube configurations and connection types.

Ready to Connnect?

If you’re ready to experience better performance, less NPT, and more efficient drilling and completions operations, Tejas Tubular is ready to start the conversation. Contact us today.