OCTG Manufacturing Excellence in the USA

OCTG Manufacturing Process

Leading OCTG Manufacturer

A U.S. OCTG Manufacturer Built on Quality and Innovation

Tejas Tubular Products stands as one of America’s most trusted manufacturers of Oil Country Tubular Goods (OCTG). For decades, we’ve built our reputation on delivering casing, tubing, couplings, and premium connections that meet the toughest industry demands. Our manufacturing process is rooted in precision and efficiency—combining upsetting, heat treatment, threading, and NDT (non-destructive testing) processes all under one roof. This full in-house quality control allows us to maintain unmatched consistency, reduce lead times, and deliver products that exceed API and customer-specific standards.

Our team of engineers, metallurgists, and technicians work with a single goal: to produce OCTG that performs flawlessly in the world’s most challenging drilling environments. Every pipe and coupling that leaves our facilities represents American manufacturing at its finest—strong, reliable, and built for performance. Learn more about our products or request a quote today

Our Manufacturing Process: From Raw Steel to Finished OCTG

At Tejas Tubular, every step of our OCTG manufacturing process is designed for precision, consistency, and quality control. We manage the entire production flow in-house—from the selection of premium steel to final inspection and testing—ensuring complete traceability and compliance with API 5CT standards (and updates). Our advanced manufacturing lines allow us to deliver casing, tubing, and couplings that meet the highest performance expectations for oil and gas applications.

1. Selecting High Quality Steel

From receipt through upsetting, heat treatment, hot sizing, NDT, threading, hydro testing, and finishing, each heat and lot is identified and recorded in our production and quality systems. Stenciling, tagging, and work-order traceability allow every finished joint, coupling, and pup joint to be tied back to its original heat and processing history. This level of documentation supports reliable MTRs, rapid field verification, and the traceability operators expect from Tejas Tubular.

Both our Houston and Stephenville Mill locations are held to the highest API standards.

Watch our Steel Pipe Mill in Action in the video below.

2. Upsetting

Hot forging of pipe ends to increase wall thickness and outer diameter (OD) for threading and stronger connections.

Tejas forges tubing and drill pipe upsets in-house according to API standards and customer requirements. This in-house capability allows us to deliver consistent quality while customizing upsets for premium and integral connections across API Tubing, Pup Joints, and premium tubing products.

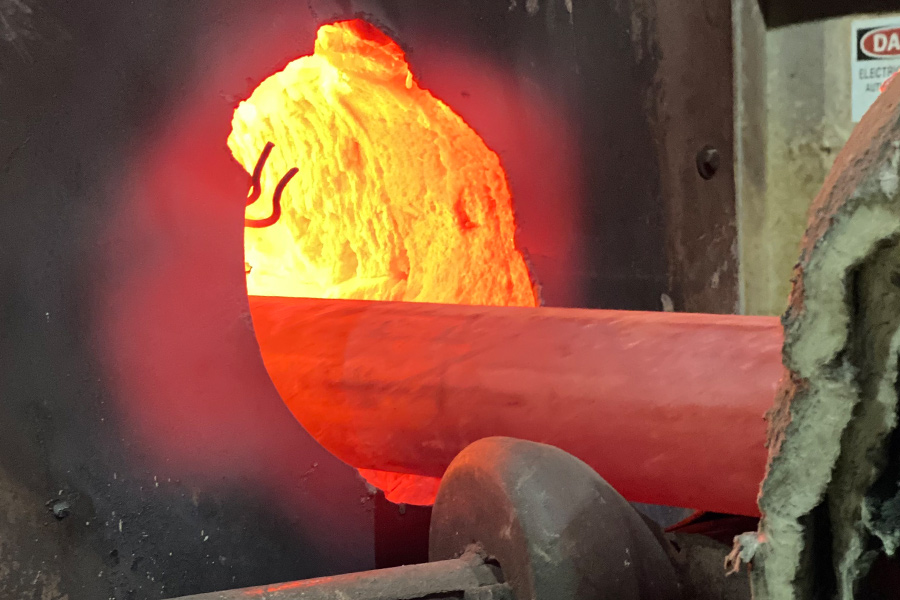

3. Heat Treatment

Strengthens and tempers the steel tube after mechanical forming.

In most OCTG manufacturing processes, heat treatment is a critical step used to enhance the steel’s strength and durability after mechanical forming operations such as upsetting. The process typically involves heating and cooling the tubular product to refine its microstructure and achieve the proper mechanical properties for downhole performance.

At Tejas Tubular, we perform multiple forms of heat treatment including quench and temper (Q&T), normalizing, and normalize and temper (N&T). Using both gas-fired and electric induction furnaces, our lines ensure uniform mechanical properties across all API Tubing and Casing products. This control results in consistent toughness and yield strength in every section we produce.

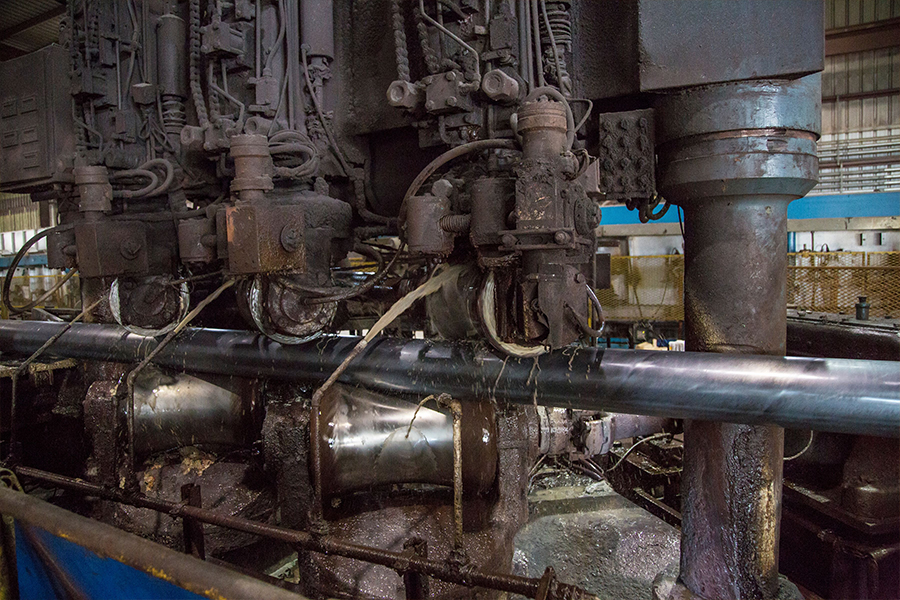

4. Hot Sizing and Straightening

After heat treatment, most OCTG manufacturers rely on mechanical sizing to meet dimensional tolerances. However, this can introduce ovality and reduce collapse resistance.

Tejas Tubular is one of the few domestic OCTG processors offering both hot sizing and hot straightening in-house.

By reshaping the pipe or casing at high temperatures (above 850°F / 454°C), we ensure every joint is perfectly round, dimensionally accurate, and able to withstand high external pressures.

This controlled process enhances collapse resistance and overall product integrity — key factors in safe, reliable well performance.

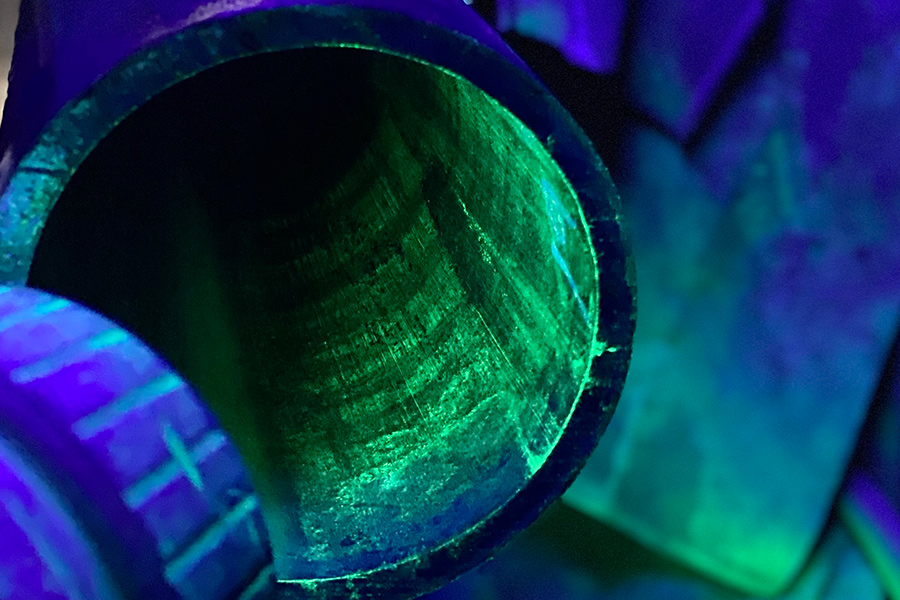

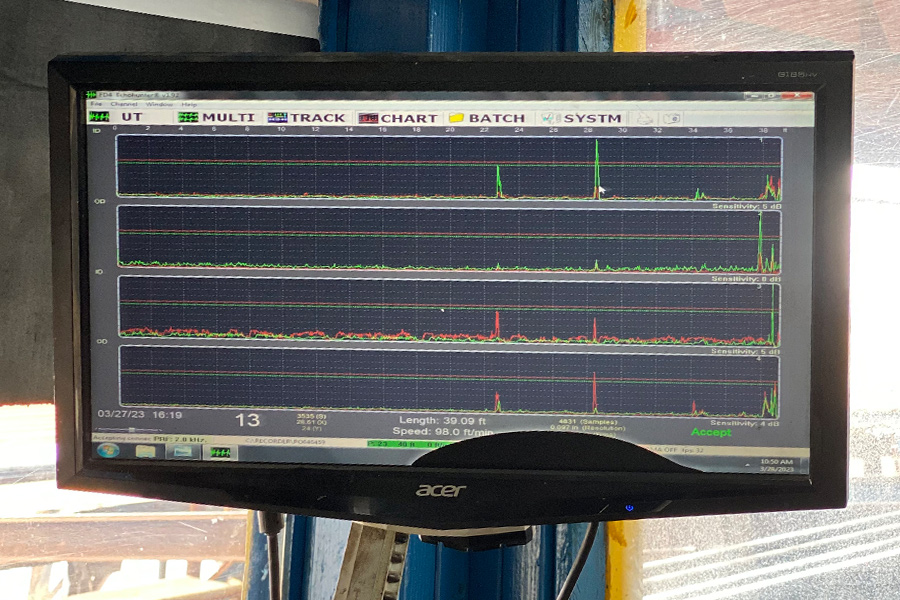

5. Inspection and Non-Destructive Testing (NDT)

Most OCTG manufacturers perform basic ultrasonic or magnetic tests at the end of production. Tejas goes beyond these minimums by incorporating NDT throughout manufacturing.

Our in-line inspection systems include ultrasonic, magnetic particle, and visual examinations to identify any surface or subsurface discontinuities. We perform full-body ultrasonic inspection (UTWL) and special end-area (SEA) inspection to ensure that only flawless Tubing, Casing, and Couplings advance to finishing.

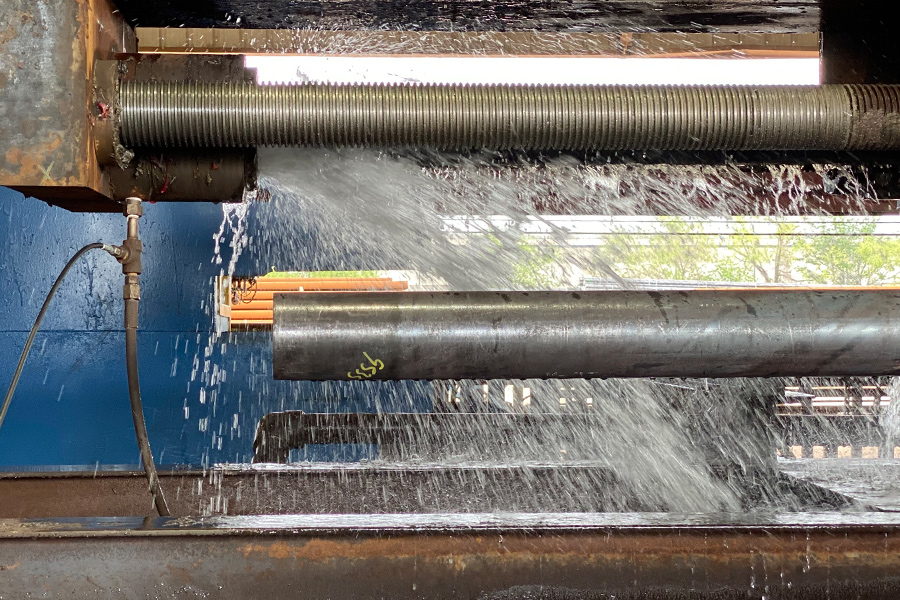

6. Hydro Testing

Hydrostatic testing verifies the internal pressure strength of OCTG before it leaves the plant. Many facilities test at lower pressures to meet only minimum standards. At Tejas Tubular, we test every joint of Casing, Tubing, and Pup Joint at pressures up to 20,000 psi for certain high-spec applications using in-line hydrostatic systems. This ensures every product meets or exceeds API 5CT requirements for pressure integrity and downhole reliability.

7. CNC Machining and Threading

Threading is a vital step in any OCTG manufacturing process, as precision threading determines how securely tubular components connect downhole. Many manufacturers outsource threading, which increases variation and potential mismatch.

At Tejas, our high-speed automated CNC threading systems produce precision-finished couplings and pins with tolerances that exceed API specifications. We maintain complete in-house control over threading profiles for Couplings, API Tubing, and Pup Joints.

We also manufacture premium tubing connections, including:

These premium connections are engineered for superior seal integrity and performance in critical well conditions.

8. Finishing and Coating

Tejas performs both phosphate treatment and protective coating entirely in-house, applying precision finishes that resist corrosion and meet API color identification standards. Each Coupling, Tubing, and Pup Joint undergoes the same rigorous finishing process, ensuring long-term durability and full compatibility across every connection.

Precision Manufacturing Across Every OCTG Product Line

Each product we manufacture follows the same vertically integrated process that defines Tejas Tubular. From heat treatment to final inspection, every piece is engineered and finished in-house for consistency, traceability, and reliability in the field. Our API-licensed manufacturing and threading facilities ensure compliance with API 5CT and customer-specific standards across all product categories.

API & Premium Tubing

Our tubing is manufactured to deliver exceptional performance in demanding oil and gas wells. Each tube undergoes controlled heat treatment, upsetting, and CNC threading to maintain strength, ductility, and dimensional precision. We offer a range of API and premium tubing products, including Spearhead, TTWS Premium Coupling, TTS6 Black, and TTS8, each engineered for superior seal integrity and connection performance.

Casing

Tejas manufactures a full range of API 5CT casing grades designed to protect wells during drilling and production. Our hot sizing and straightening operations ensure precise OD control and high collapse ratings. With in-house heat treating, NDT, and hydro testing, our casing products maintain exceptional mechanical integrity and consistent quality from joint to joint.

Couplings

Every coupling we produce is CNC-machined and threaded in-house to deliver tight tolerances and superior make-up performance. Our in-house phosphating and coating processes add corrosion protection and ensure compatibility with Tejas and third-party tubulars. Whether standard API or premium, Tejas couplings are engineered for precision, longevity, and field reliability.

Pup Joints

Our pup joints are manufactured using the same advanced OCTG processes as our tubing and casing. From upsetting and heat treating to threading and hydro testing, every pup joint is held to API and customer specifications. Each is phosphate-coated, hydro-tested, and inspected for dimensional accuracy, ensuring they perform flawlessly in critical well environments.

FAQs

Frequently Asked Questions About OCTG Manufacturing

What does OCTG manufacturing mean?

OCTG manufacturing refers to the production of Oil Country Tubular Goods, including casing, tubing, and drill pipe, used in oil and gas wells. These products must meet current API 5CT standards for strength and performance.

What is the OCTG manufacturing process?

The OCTG manufacturing process includes steel selection, heat treating, upsetting, sizing, threading, testing, and coating steel tubes to ensure they meet mechanical and dimensional specifications for downhole use.

What are the main types of OCTG products?

The three main OCTG product types are casing, tubing, and drill pipe. Tejas Tubular also manufactures couplings and pup joints that connect and reinforce these critical well components.

Why is in-house OCTG manufacturing important?

In-house OCTG manufacturing ensures full quality control, faster lead times, and consistent product integrity. Tejas performs every process—heat treatment, threading, inspection, and coating—within its U.S. facilities.

What standards apply to OCTG manufacturing?

OCTG products must meet American Petroleum Institute (API) specifications, primarily API 5CT, which governs chemical composition, mechanical properties, and testing requirements.