Quality Manufacturing Processes

Focused on Quality

As one of the leading manufacturers of Oil Country Tubular Goods in the USA, we incorporate our core values into our manufacturing model consisting of upsetting, heat treatment, NDT, and threading operations. We are licensed and capable of producing grades J55, K55, L80, N80, C90, T95, C110, P110, Q125, E75, X95, G105, and S135. Our threading capabilities include EUE, NUE, USS IMP BTT, STC, LTC and BTC connections along with API rotary shouldered connections and all our semi-premium and premium connections.

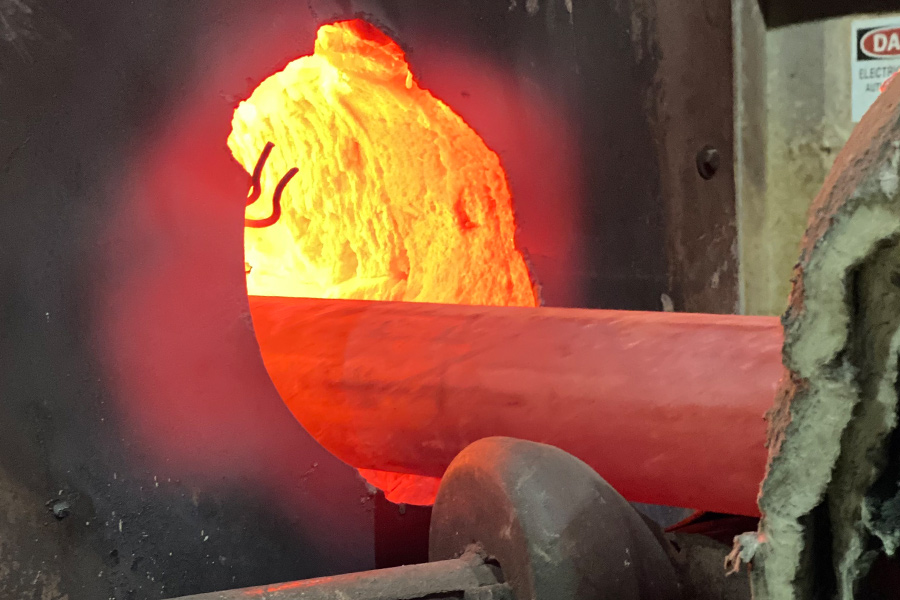

Heat Treating

We perform three types of heat treatment: quench & temper (Q&T), normalizing, and normalize & temper (N&T). We use gas fired furnaces and electrical induction furnaces for heat treatment of products. We have multiple heat treatment lines to support various product needs and deliver orders on time.

CNC Machining

Our high-speed automated CNC threading capabilities allow us to produce precision-finished couplings and pins; our in-house tolerance on thread elements of 8rd and buttress are half of API limits.

Straightening

All our casing products undergo hot straightening after temper. Tubing products are inspected for straightness after heat treatment to ensure compliance with our in-house and API requirements. Any questionable product is subjected to either cross-roll or pin straightening.

Hot Sizing

We are the only processor with hot sizing and hot straightening capabilities in the U.S. To ensure the OD of the heat-treated pipe are within the tolerances of API Specification 5CT all our casing is hot sized at temperatures higher than 850°F [454°C]. Our hot sizing operation, after tempering, substantially reduces ovality of the casing and enhances the collapse ratings.

Upsetting

We forge tubing and drill pipe upsets in accordance with API specifications and your requirements. Special upsets for premium and integral connections can also be forged upon request.

Hydro Testing

All our facilities have in-line hydrostatic testers to comply with API requirements. We also have a custom-built plain end hydro tester which can attain test pressures as high as 20,000 psi [103,421 kPa], to accommodate your special testing requirements.

It’s All About Connections!

Tejas Tubular is your #1 Resource for quality manufacturing,

engineering, project management and service.

API TUBING

We are the most comprehensive tubing provider in North America since 1990.

CASING

We are the only processor with hot sizing and hot straightening capabilities.

PUP JOINTS

Manufactured from the highest quality API seamless tubing, and per API 5CT requirements.

COUPLINGS

All of the couplings manufactured by us are made from coupling stock of handpicked seamless mills.

DRILL PIPE

We manufacture API drill pipe and horizontal directional drill rods.

PROTECTORS

Specifically designed and manufactured for TT pipes — protect your investment from the environment.

Ready to Connnect?

If you’re ready to experience better performance, less NPT, and more efficient drilling and completions operations, Tejas Tubular is ready to start the conversation. Contact us today.