by tejastubular | May 15, 2023

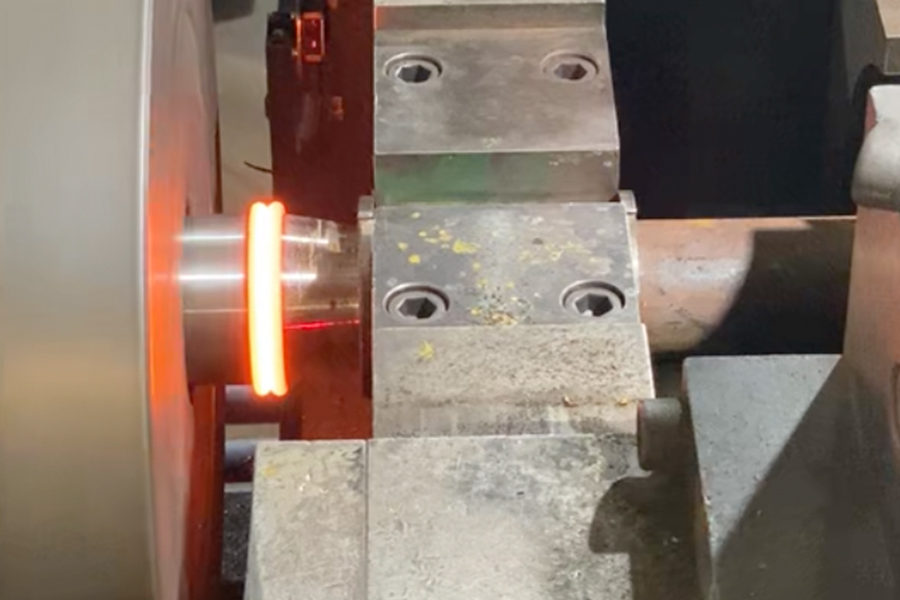

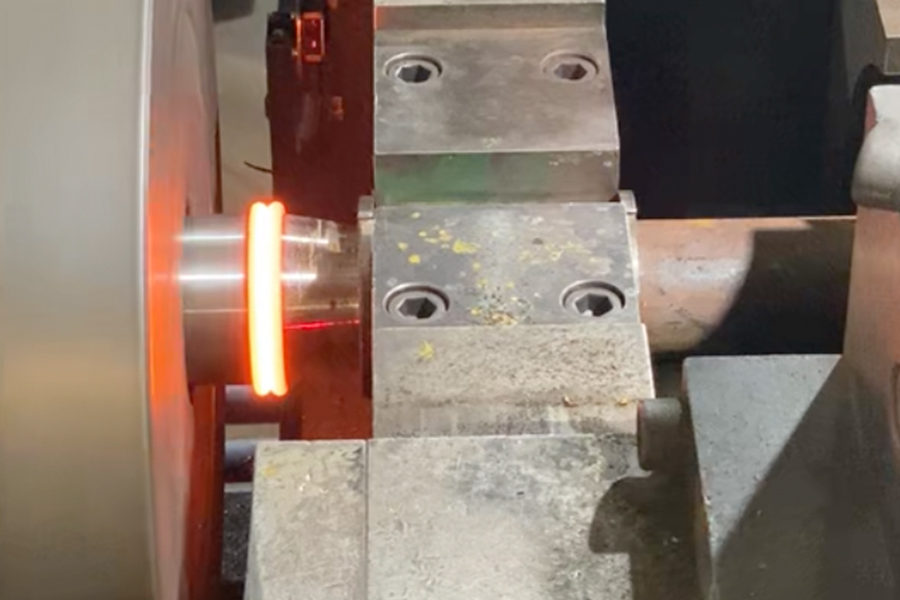

Our company utilizes in-house inertia welding machines to fuse machined tool joints to tube ends through friction heat. This process is used to create various products, including our line of new and reconditioned workover string joints.

by tejastubular | May 15, 2023

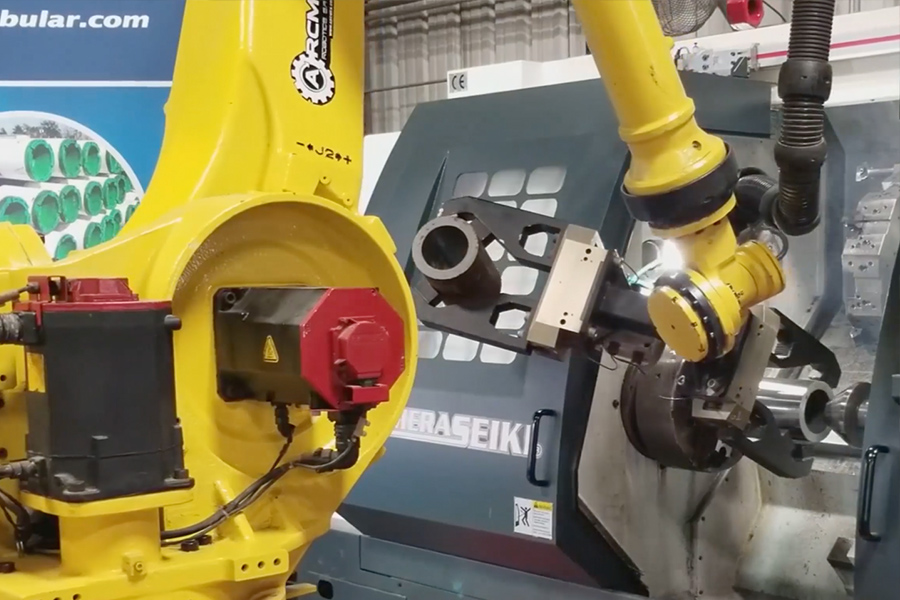

Leveraging state-of-the-art CNC machines and automated machining technology, our end-finishing production lines ensure the highest caliber precision threading. Our tubes go above and beyond API standards and are expertly equipped with Tejas Tubular couplings for...

by tejastubular | May 16, 2023

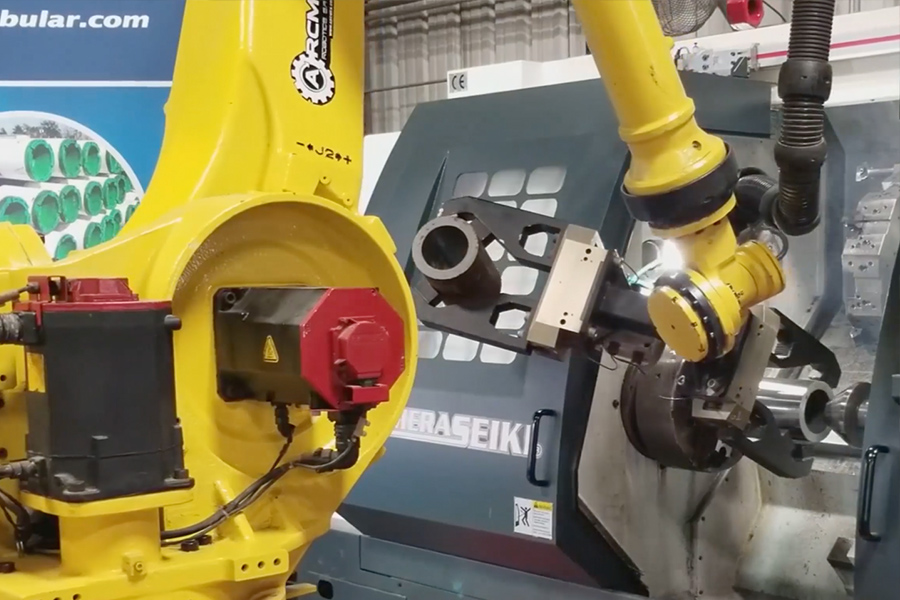

Our in-house handling tool is designed specifically for gripping our couplings for maximum effectiveness.

by tejastubular | May 16, 2023

Our company has implemented an automated line for processing pup joints, streamlining the inspection-to-finish process. This not only boosts the overall production of pup joints but also enhances the safety of our employees.

by tejastubular | May 15, 2023

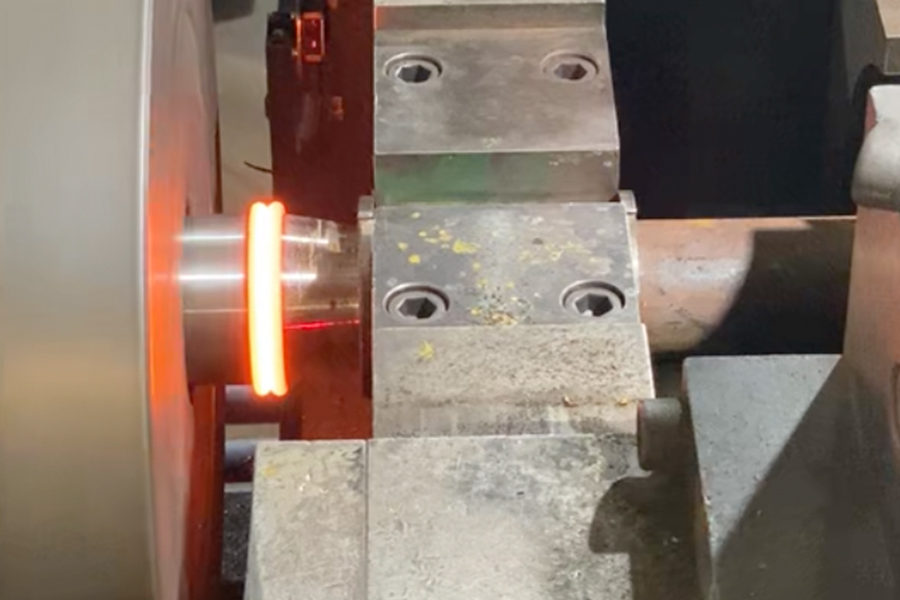

We manufacture pup joints by shaping heavy wall mechanical tubing with high precision and tolerance CNC technology. This allows us to achieve exceptional dimensional tolerance and surface finish for our pup joints.