by tejastubular | May 15, 2023

Our tubing source is carefully selected from top mills to ensure exceptional quality with great attention to detail.

by tejastubular | May 15, 2023

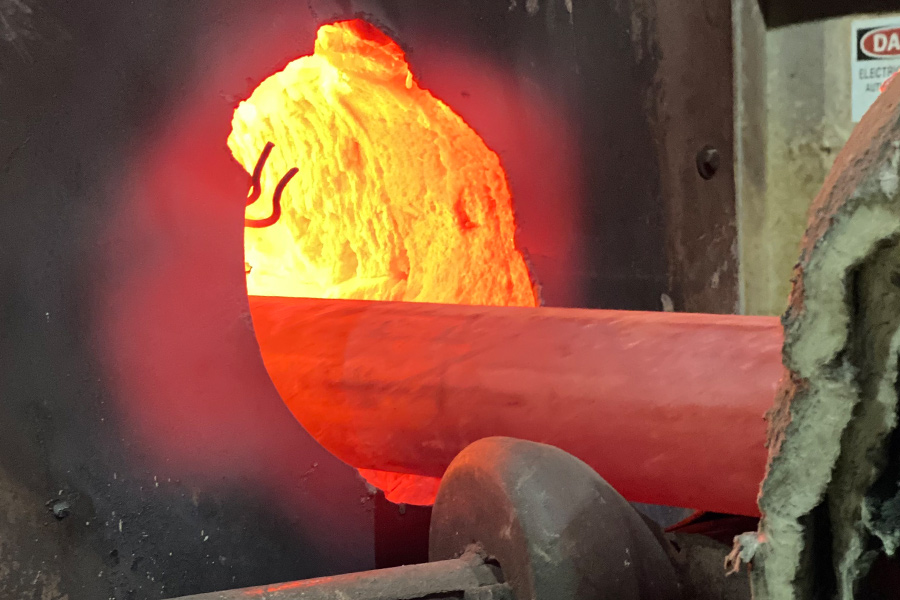

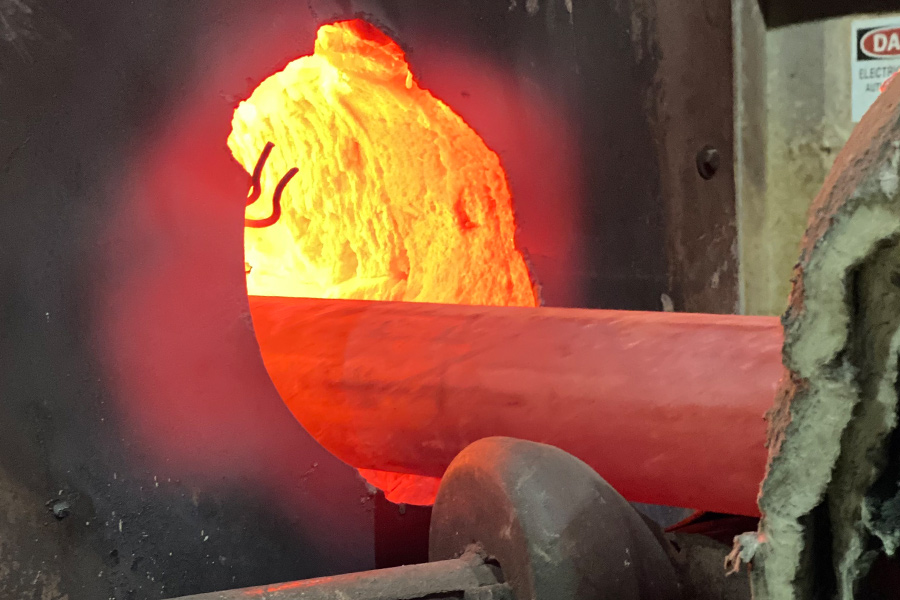

We have multiple heat-treating lines to ensure quick turnarounds. Our manufacturing process includes two types of heat treatment: quench and temper (Q&T), and normalizing (norm). Our team uses induction furnaces for the heat treatment of products.

by tejastubular | May 15, 2023

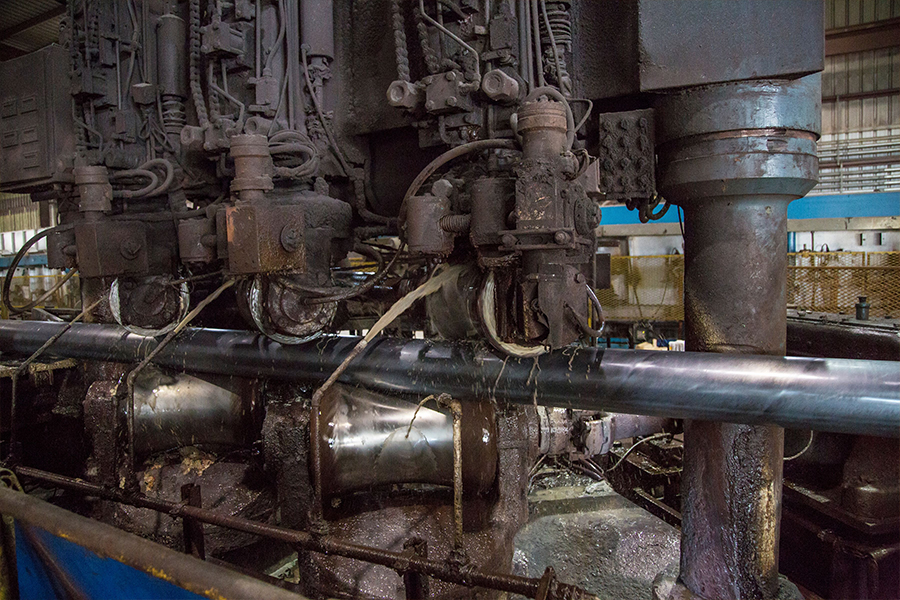

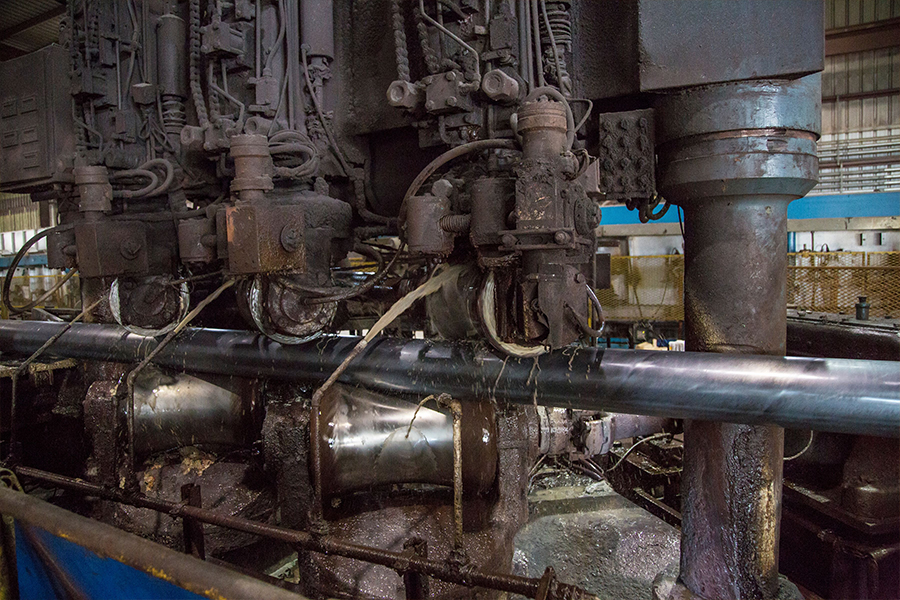

Furnace energy can sometimes cause slight pipe bending. Post tempering, pipes pass through a cross roll straightener to realign. After passing QC, pipes proceed to the next step or storage for future orders.

by tejastubular | May 15, 2023

We start with a specialized chemistry carbon alloy tube body. Our 4130 Carbon alloy, green tube starts its journey by transiting a slot furnace to be heated to 2,300 degrees. Once at the required temperature, the end is secured in a set of precision machined dies. The...

by tejastubular | May 15, 2023

Our dedicated EMI units perform continuous inspections of pipe bodies, ensuring the assessment of longitudinal and transverse qualities, wall thickness, and component grades. These units are equipped to handle pipe outer diameters ranging from 2 3/8″ to 9...