by tejastubular | May 15, 2023

Our dedicated EMI units perform continuous inspections of pipe bodies, ensuring the assessment of longitudinal and transverse qualities, wall thickness, and component grades. These units are equipped to handle pipe outer diameters ranging from 2 3/8″ to 9...

by tejastubular | May 15, 2023

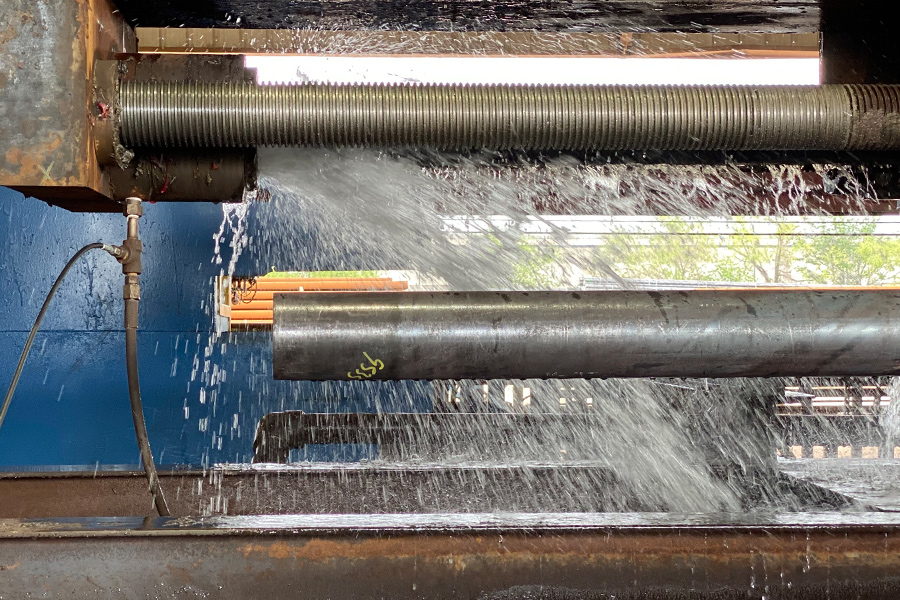

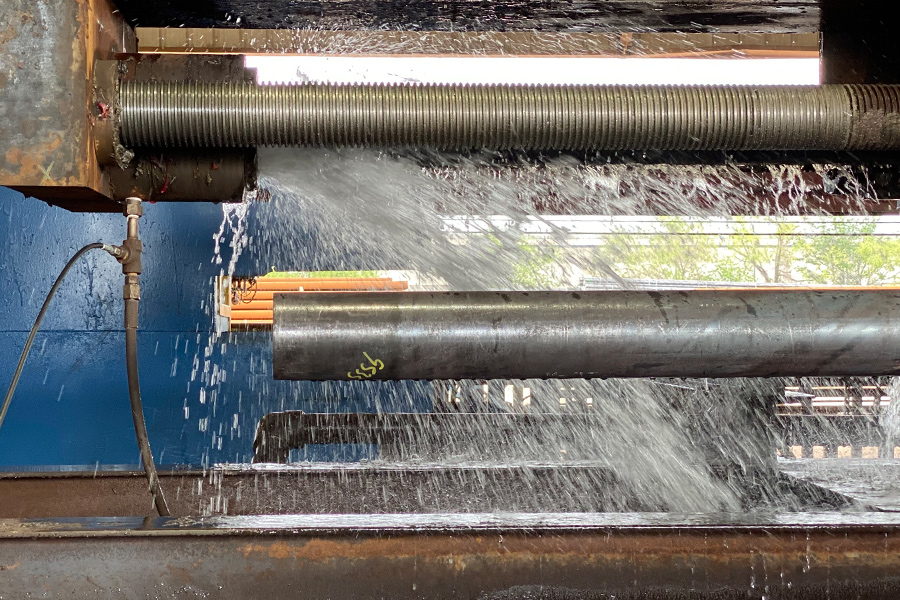

Our state-of-the-art hydro-testing equipment is versatile, able to test standard API products as well as handle higher rates, varying product lengths, and a wide range of pressures.

by Ashley Zamora | Aug 31, 2023

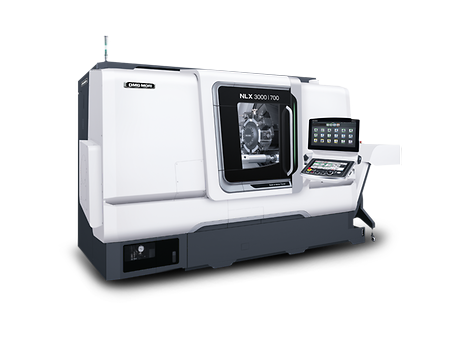

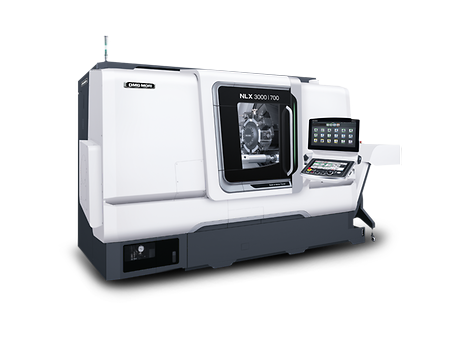

Our dedication to enhancing threading capabilities remains unwavering as we consistently integrate cutting-edge CNC machines and automated machining technology. These advancements ensure the utmost precision in threading on our premium end-finishing production...

by tejastubular | May 15, 2023

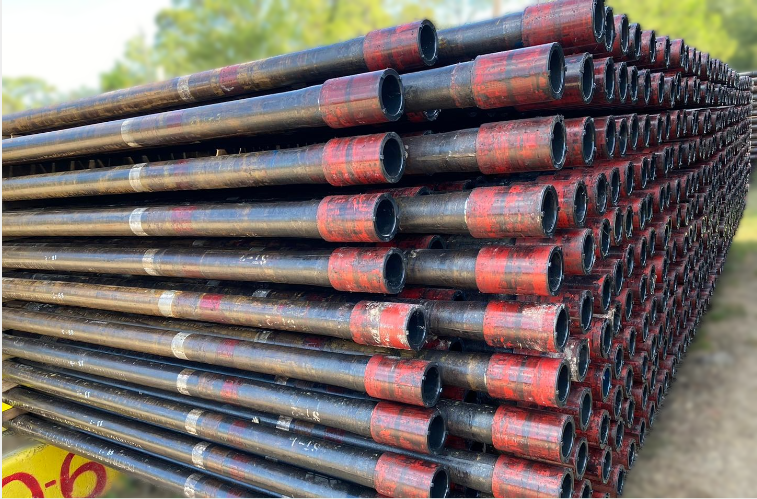

This procedure enhances corrosion resistance and establishes a robust bond, laying the groundwork for subsequent painting. Furthermore, it ensures optimal thread surface preparation during the pipe assembly process.

by Ashley Zamora | Sep 5, 2023

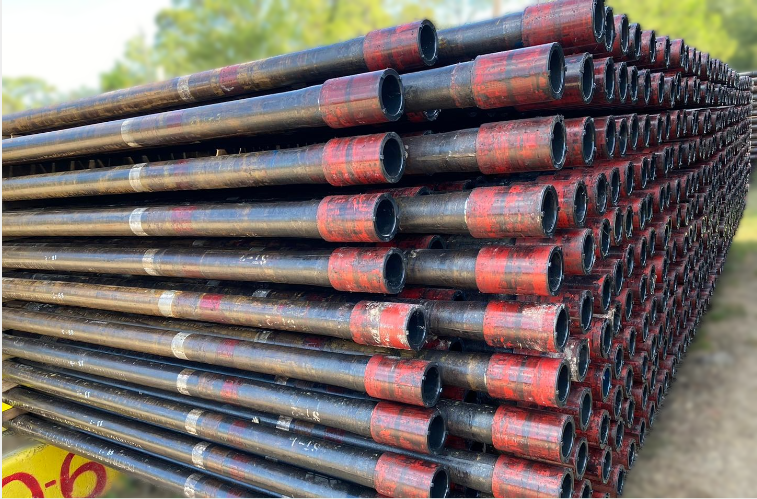

To prevent rusting, we apply a clear coat to the pipe’s exterior and adhere to API specifications by adding two colored bands to assess the product’s quality and condition.