by tejastubular | May 15, 2023

Our tubing source is carefully selected from top mills to ensure exceptional quality with great attention to detail.

by tejastubular | May 15, 2023

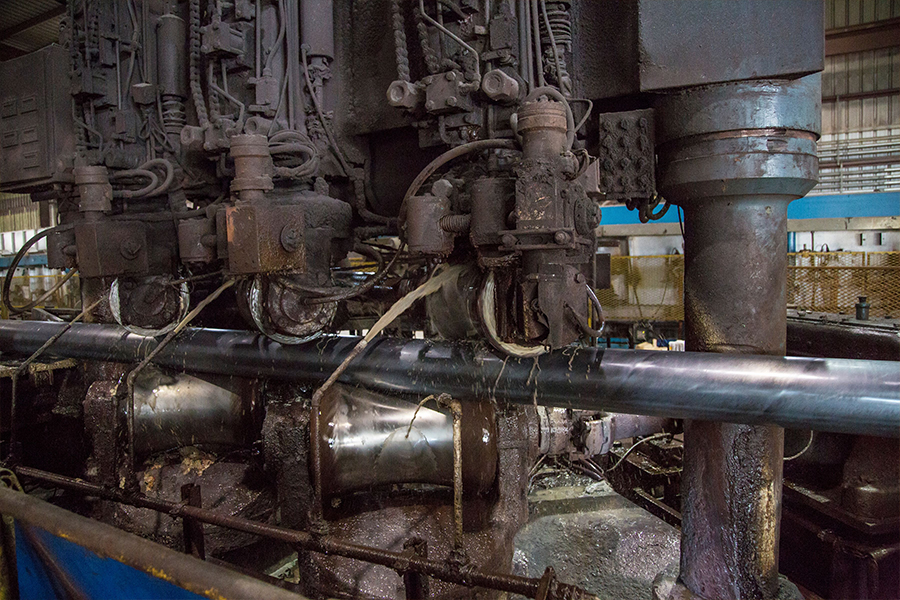

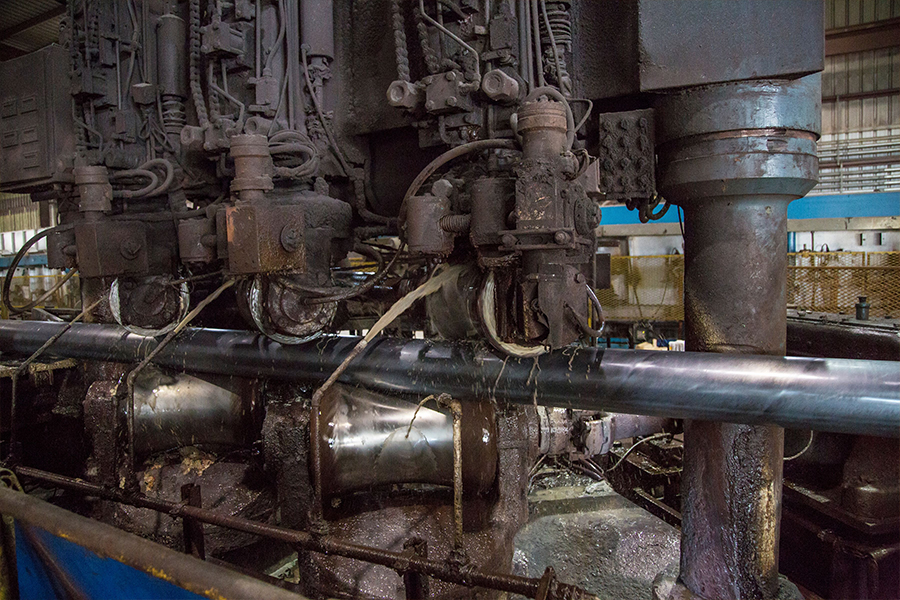

Our in-house upsetters empower us with the expertise to skillfully hot forge tubing ends while strictly complying with API specifications. Furthermore, we provide the versatility to tailor these ends to match the unique demands of our esteemed clientele...

by tejastubular | May 15, 2023

Furnace energy can sometimes cause slight pipe bending. Post tempering, pipes pass through a cross roll straightener to realign. After passing QC, pipes proceed to the next step or storage for future orders.

by tejastubular | Jun 21, 2023

By utilizing the wet magnetic particle technique, we conduct inspections on pipe ends, including those up to 18 inches in size, addressing potential oversights that can occur during UTWL and EMI inspections.

by tejastubular | May 15, 2023

Our dedicated EMI units perform continuous inspections of pipe bodies, ensuring the assessment of longitudinal and transverse qualities, wall thickness, and component grades. These units are equipped to handle pipe outer diameters ranging from 2 3/8″ to 9...