Quality Assurance

Quality Assurance and

Process Control

Our Quality Policy:

“Tejas Tubular is committed to customer satisfaction through continuous process improvement.”

At the heart of Tejas Tubular is a seasoned and committed team, unwavering in our dedication to top-tier manufacturing. From engineering and product design to material choices and rigorous testing, every aspect is harmonized to guarantee unmatched durability and peak performance in the field.

Our Quality Policy shapes and propels our operations, guiding us to produce products that exceed API standards and consistently outperform your expectations.

Mechanical Testing Laboratory

Equipped with state-of-the-art mechanical testing facilities, our labs meet rigorous API standards and are proficient in heat treatment process validation. Our comprehensive capabilities cater to a spectrum of testing requirements.

- Tensile testing (round and strap samples)

- Impact testing at -50° F

- Chemical analysis

- Hardness testing (HRB, HRC, and Brinell)

- Bend tests

- Flattening tests

- Metallographic sample analysis

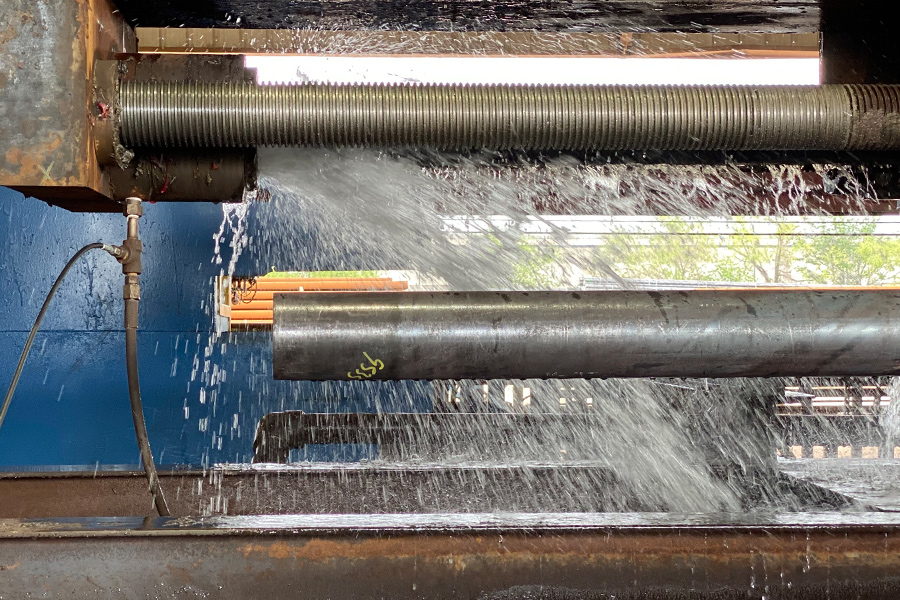

Non-destructive testing

Our skilled inspectors employ various NDT equipment across all locations to meet your diverse inspection needs. Our NDT capabilities include the following:

- Hydrostatic Testing: Equipped to handle up to 20,000 psi, our hydro testing gear is versatile and adjustable to accommodate different lengths.

- Electromagnetic Inspection (EMI): Our specialized EMI units carry out continuous inspections of pipe bodies, verifying longitudinal, transverse, wall thickness, and component grades, handling pipe ODs from 2 3/8″ to 9 5/8″.

- Ultrasonic Weld-line Inspection (UTWL): Following hydrostatic testing of

all ERW casing and P110, Q125 tubing, we conduct UTWL on the weld seam to pinpoint potential imperfections. - Special End Area Inspection (SEA): Utilizing the wet magnetic particle technique, we examine pipe ends (up to 18 inches) that might be missed during UTWL and EMI inspections.

- Full Body Ultrasonic Testing (FBUT): Our rigorous ultrasonic examination process ensures that tubing pup joints are fully inspected, covering their entire body and length, to detect longitudinal or transverse defects.

IN-LINE QUALITY CONTROL:

EXCEEDING PRECISION AND EXCELLENCE

Our commitment to precision doesn’t merely meet API standards – it surpasses them. We’ve reduced the variability in material and connection properties, ensuring that our products exceed API limits in accuracy. Even our thread elements on API connections boast a tolerance level that’s half of what API mandates, demonstrating our unyielding pursuit of unparalleled precision.

This focus on in-line QC is pivotal in our journey to consistently exceed our standards of excellence, setting us apart in an industry where we continually raise the bar.

STATISTICAL PROCESS CONTROL:

DATA-DRIVEN EXCELLENCE

“What cannot be measured, cannot be improved” – Guided by this principle, we diligently capture data from our in-line QC and subject it to periodic analysis. This strategic evaluation verifies our performance and spotlights areas demanding prompt intervention.

By doing so, we uphold our operational benchmarks and assess supplier performance effectively. Over the years, the insights from SPC have been instrumental, enabling us to make pivotal decisions that have fine-tuned and optimized our manufacturing processes.

It’s All About Connections!

Tejas Tubular is your #1 Resource for quality manufacturing,

engineering, project management and service.

PREMIUM TTWS

TTWS Connection is a threaded and coupled, high torque, six threads per inch, double start with straight-to-taper, providing deeper stabbing and faster make-ups.

PREMIUM TTS-6 Black

Our premium TTS-6 connections are designed to meet and exceed the challenges of today’s energy exploration and production needs.

PREMIUM TTS-8

Our premium TTS-8 connections are designed to exceed the challenges of today’s energy exploration and production needs.

API TUBING

Since 1990, we have proudly stood as North America’s leading and most comprehensive API tubing provider.

PUP JOINTS

Our pup joints are manufactured from the highest quality API seamless tubing and per API 5CT requirements.

COUPLINGS

Our coupling is crafted from coupling stock carefully selected from top-tier seamless mills.

PROTECTORS

Our protectors are exclusively fabricated for TT pipes, safeguarding your investment from environmental factors.

DRILL PIPE

Manufacture drill pipes that adhere to API standards as well as horizontal directional drill rods.

Crossovers

Tejas provides crossovers facilitating seamless connections between varying tube configurations and connection types.

Ready to Connnect?

If you’re ready to experience better performance, less NPT, and more efficient drilling and completions operations, Tejas Tubular is ready to start the conversation. Contact us today.