Continually Making Things Better

We are committed to customer satisfaction through continuous process improvement. Our process works together to ensure optimal durability and performance in the field.

Explore Our Process…

Saw Cut

Utilizing high-speed production band saws, our skilled team expertly cuts premium tubes to precise lengths and square dimensions, ensuring optimal fit for couplings.

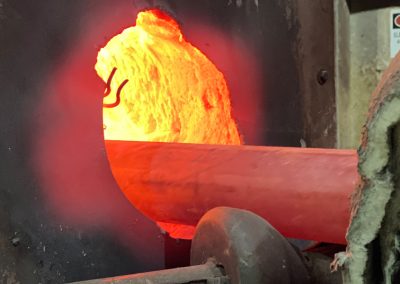

Upset

Our in-house upsetters empower us with the expertise to skillfully hot forge tubing ends while strictly complying with API specifications. Furthermore, we provide the versatility to tailor these ends to match the unique demands of our esteemed clientele precisely.

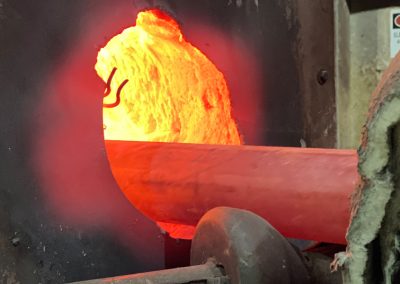

Heat Treatment

Our facility has several heat-treat lines that utilize induction, gas-fired furnaces, and two distinct heat treatment methods: quench and temper, and normalizing.

Heat Treatment

We use a specialized heat-treat line for timely delivery. Our team employs induction furnaces for high-quality quench and temper and normalizing heat treatments. Our efficient line ensures prompt order delivery.

Hot Sizing & Hot Straightening

Our company offers unique hot-sizing and hot-straightening capabilities. Our in-line hot-sizer controls tube dimensions, reducing ovality, and we hot-size all casing during wet magnetic particle inspection. We also inspect all pipe ends for added safety and assurance.

Fully Equipped Mechanical Testing Laboratory

Our casings undergo rigorous non-destructive testing to ensure high quality and reliability. You can trust that our products meet the highest standards.

Hydro

Our state-of-the-art hydro-testing equipment is versatile, able to test standard API products as well as handle higher rates, varying product lengths, and a wide range of pressures.

Ultrasonic Weld-Line Inspection (UTWL)

We rigorously examine every weld seam to identify any defects and apply magnetic particle inspections on pipe ends to pinpoint any steel or processing-related concerns.

Straightening

Furnace energy can sometimes cause slight pipe bending. Post tempering, pipes pass through a cross roll straightener to realign. After passing QC, pipes proceed to the next step or storage for future orders.

SEA Inspection

By utilizing the wet magnetic particle technique, we conduct inspections on pipe ends, including those up to 18 inches in size, addressing potential oversights that can occur during UTWL and EMI inspections.

Turn and Bore

Our commitment to precision is exemplified through our utilization of turn and bore methods, which guarantee uniformity in inner and outer diameters while adhering to specified tolerances.

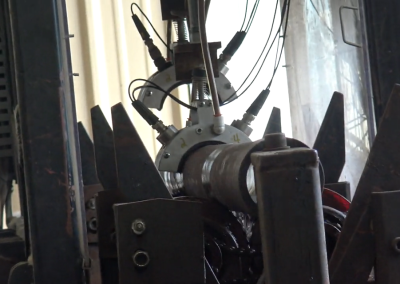

EMI Inspection

Our dedicated EMI units perform continuous inspections of pipe bodies, ensuring the assessment of longitudinal and transverse qualities, wall thickness, and component grades. These units are equipped to handle pipe outer diameters ranging from 2 3/8″ to 9 5/8″.

Hydro

Our state-of-the-art hydro-testing equipment is versatile, able to test standard API products as well as handle higher rates, varying product lengths, and a wide range of pressures.

Threading

Our dedication to enhancing threading capabilities remains unwavering as we consistently integrate cutting-edge CNC machines and automated machining technology. These advancements ensure the utmost precision in threading on our premium end-finishing production lines.

Full Body Ultrasonic Inspection

As industry trailblazers, we are proud to introduce the groundbreaking Full Body Ultrasonic Inspection for our Pup Joints. This advanced inspection method significantly enhances the detection of cracks, pits, and other imperfections within the pup joint’s interior diameter.

Threading

We use advanced technology CNC machines and automated machining for precision threading on our end-finishing production lines. Our tubes exceed API standards and are fitted with Tejas Tubular couplings.

Threading

In our end-finishing production lines, we employ advanced CNC machines and automated machining technology for precise threading. This meticulous process ensures that our tubes not only meet but surpass API standards, offering compatibility with both Tejas Tubular couplings and your preferred couplings.

Threading

Our commitment to precision threading is exemplified by our use of cutting-edge CNC machines and automated machining technology. These advanced tools ensure that all our couplings not only meet but exceed API standards, providing a perfect fit for your specific requirements.

Ultrasonic Weld-Line Inspection (UTWL)

Each weld seam undergoes meticulous scrutiny to detect imperfections. Additionally, we employ magnetic particle inspections on pipe ends to precisely identify steel or processing-related issues.

Special End Area Inspection

Wet magnetic particle testing detects surface and shallow subsurface defects in non-destructive testing, including longitudinal and transverse defects.

Phosphate

This procedure enhances corrosion resistance and establishes a robust bond, laying the groundwork for subsequent painting. Furthermore, it ensures optimal thread surface preparation during the pipe assembly process.

Phosphate

This procedure enhances corrosion resistance and establishes a robust bond, laying the groundwork for subsequent painting.

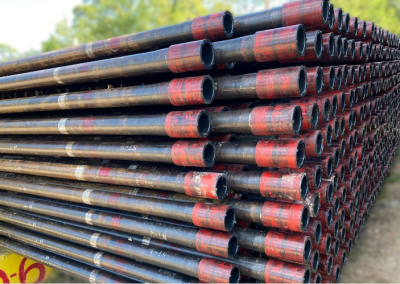

Coating

To prevent rusting, we apply a clear coat to the pipe’s exterior and adhere to API specifications by adding two colored bands to assess the product’s quality and condition.

Threading

We use CNC machines and automated machining for precise threading on our end-finishing production lines. Our tubes exceed API standards and feature Tejas Tubular couplings.

Coating

Following the completion of our meticulous manufacturing process, the pup joints proceed to our cutting-edge painting facility. Tailored to their respective grades, each pup joint receives a unique color coating, adding a personalized touch to our quality craftsmanship.

Coating

Our couplings proceed to our painting facility to ensure each coupling receives a unique color coating, adding a personalized touch to our quality craftsmanship.

It’s All About Connections!

Tejas Tubular is your #1 Resource for quality manufacturing,engineering, project management and service.

PREMIUM TTWS

TTWS Connection is a threaded and coupled, high torque, six threads per inch, double start with straight-to-taper, providing deeper stabbing and faster make-ups.

PREMIUM TTS-6 Black

Our premium connections are designed to meet and exceed the challenges of today's energy exploration and production needs.

PREMIUM TTS-8

Our premium connections are designed to meet and exceed the challenges of today's energy exploration and production needs.

API TUBING

Since 1990, we have proudly stood as North America's leading and most comprehensive tubing provider.

CASING

One of the few processors with the capabilities for hot sizing and hot straightening.

PUP JOINTS

Manufactured from the highest quality API seamless tubing and per API 5CT requirements.

COUPLINGS

Our coupling is crafted from coupling stock carefully selected from top-tier seamless mills.

PROTECTORS

Exclusively tailored and fabricated for TT pipes, safeguard your investment from environmental factors.

DRILL PIPE

Manufacture drill pipes that adhere to API standards as well as horizontal directional drill rods.

ACCESSORIES

Tejas provides crossovers facilitating seamless connections between varying tube configurations and connection types.

Ready to Connnect?

If you’re ready to experience better performance, less NPT, and more efficient drilling and completions operations, Tejas Tubular is ready to start the conversation. Contact us today.