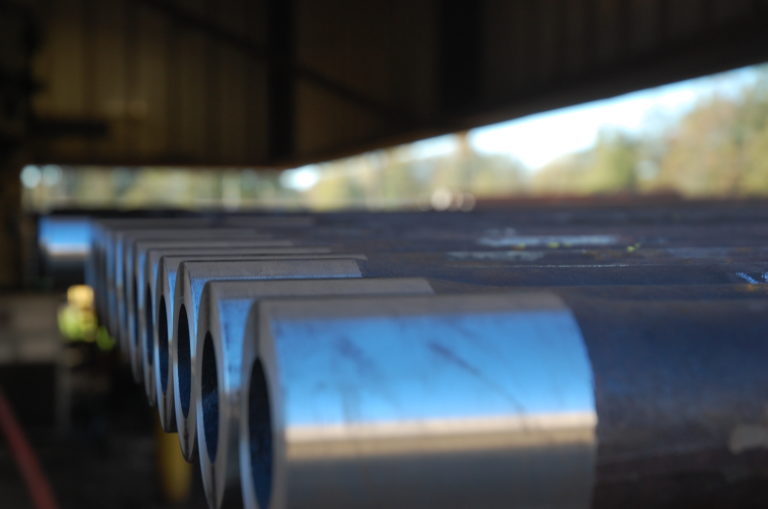

In order to get the best, and most consistent, weld on the inertia welder, the forged tubes need to have their outside diameters turned down and their weld surfaces machined (facing). This ensures that the weld area on each part being fused is equal in diameter and, that the faces are bonding uniformly during the inertia weld process.

Weld Prep: “Turn & Face”

Drill Pipe